In the epoxy and polyaspartic coating world, there are a whole lot of terms and processes that can be a bit confusing. Here’s a quick guide to what some epoxy floor terms mean. Hopefully you can use them as a reference when seeking out your new epoxy flooring solution.

Epoxy Floor Terms: Epoxy Coatings

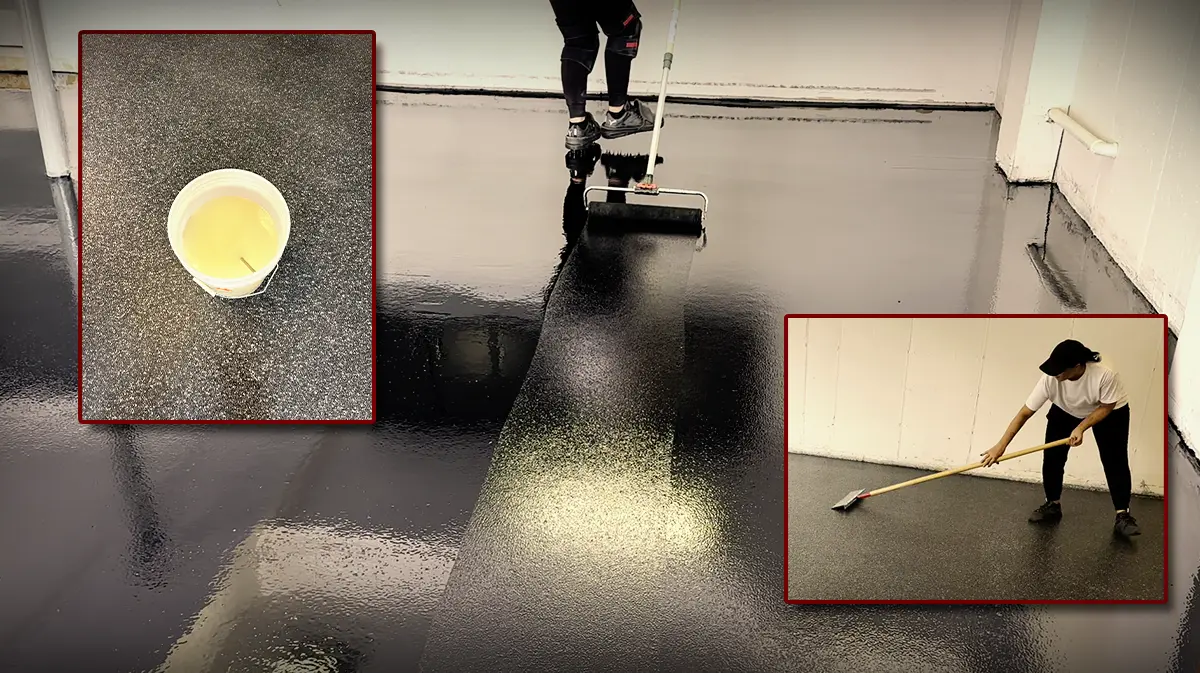

An epoxy coating is the go-to solution for durable, long-lasting flooring. These coatings consist of a resin (Part A) and hardener (Part B) that when mixed together initiate a chemical reaction. These “high-build”, slow-cure coatings bond strongly with concrete. It’s precisely the high-build (read “thick”) and slow-cure properties of an epoxy that make it a superb moisture-mitigating primer coat. It has the time to deeply penetrate the substrate (a full day) and once cured, provides a thick, strong barrier.

Furthermore, as moisture wicks up the porous concrete producing upward hydrostatic pressures, this primer coat acts as a strong moisture vapor barrier. In Cincinnati, an epoxy primer is perfect for garages, basements, and commercial spaces. However, epoxies do have disadvantages. They fade in the presence of UV light. Hence, if used as a primer, color or topcoat, they need to be covered with e.g., flakes or subsequent color coat.

Epoxy Floor Terms: Polyaspartic Coatings

Polyaspartics (aliphatic polyureas) are quick-cure coatings. Once fully cured, they provide extreme UV and chemical resistance. For this reason, they’re unmatched as clear topcoats! However, they do have a downside. These quick-cure coatings cure even quicker in the presence of moisture in the concrete. So quick, in fact, that when used as primer coats (like in “1-day” systems), they don’t have the time to deeply penetrate the concrete. Hence, the thin, poorly bonded primer has a propensity to delaminate under high hydrostatic pressures. In Cincinnati, where weather conditions vary, polyaspartics can be used as topcoats for outdoor spaces (including garages), but should be avoided as primer coats.

Epoxy Floor Terms: Polyurethane Coatings

Polyurethanes are often used as color or topcoat to add an extra layer of protection. They are ideal for high-traffic areas where the substrate is subject to wear and tear and areas exposed to extreme UV light. However, polyurethanes can be somewhat odorous and are susceptible to staining from hot tires (called “plasticizer migration”). So, typically, their use is restricted to exterior spaces not exposed to vehicular traffic (i.e., patios, walkways, etc.).

Garage Floor Coating

In Cincinnati, the term garage floor coating usually refers to epoxy and/or polyaspartic coatings that are layered, one on top of the other, to protect the garage floor. These multi-layered coatings protect the concrete substrate from moisture, chemical spills, tire marks, and impacts. They’re tough enough to handle the wear from cars, lawnmowers, and other heavy equipment, while adding a sleek, polished look to your garage space.

Concrete Paint

Concrete paint is sometimes a term used by homeowners to describe what is actually an epoxy or polyaspartic coating, though that’s technically inaccurate. While concrete paint is a cheaper, more temporary solution, it doesn’t provide the same protection as a high-quality coating. In Cincinnati, if you’re looking for durability, epoxy or polyaspartic coatings are the way to go.

Flake System

A flake system is a coating system that incorporates polyvinyl acetate (thermoplastic) or mica stone flakes. They are “broadcast” into the wet primer coat to add color, depth and texture to your floor (and to a degree, some slip resistance). Full flake coating systems (whereby the flakes are broadcast “to rejection) are the thickest and best warranted flooring. They’re super durable and can last decades if installed professionally.

Mica Flakes

Mica flakes are the way to go if you’re after a more sophisticated finish. These natural mineral flakes give your epoxy floor a reflective sheen that can elevate the look of any space. Popular in high-end garages or even commercial showrooms in Cincinnati, mica flakes provide a unique, shimmering surface that stands out.

Moisture Mitigation

In Cincinnati, where humidity can cause moisture to seep through concrete, moisture mitigation is key. It’s crucial to manage moisture vapor transmission (moisture that seeps up through the porous concrete) with a moisture vapor barrier. Mitigating for moisture with help prevent prevent future bubbling or peeling. Using a moisture-mitigating, 100%-solids epoxy primer ensures the primer coat bonds properly with the concrete. (The entire coating system is only as strong as its primer coat!).

Choosing GatorGuard

For homeowners and businesses in Cincinnati, GatorGuard offers top-quality epoxy and polyaspartic coatings designed to withstand local weather conditions. Whether you need protection for your garage, basement, or commercial space, understanding these key terms helps you choose the right solution for your flooring needs. With options for design, durability, and quick installation, GatorGuard has the expertise to transform your floors into something functional and stylish.

Share this Post