When considering epoxy flooring / concrete coatings for your garage, basement, or commercial space in Detroit, you may come across some technical terms that can be confusing. Let’s break down some typical epoxy floor industry terms in a question-and-answer format to help you understand how these coatings work and why they are important for your space.

Epoxy Floor Industry Terms – Q: What is an epoxy coating, and why should I use it for my garage?

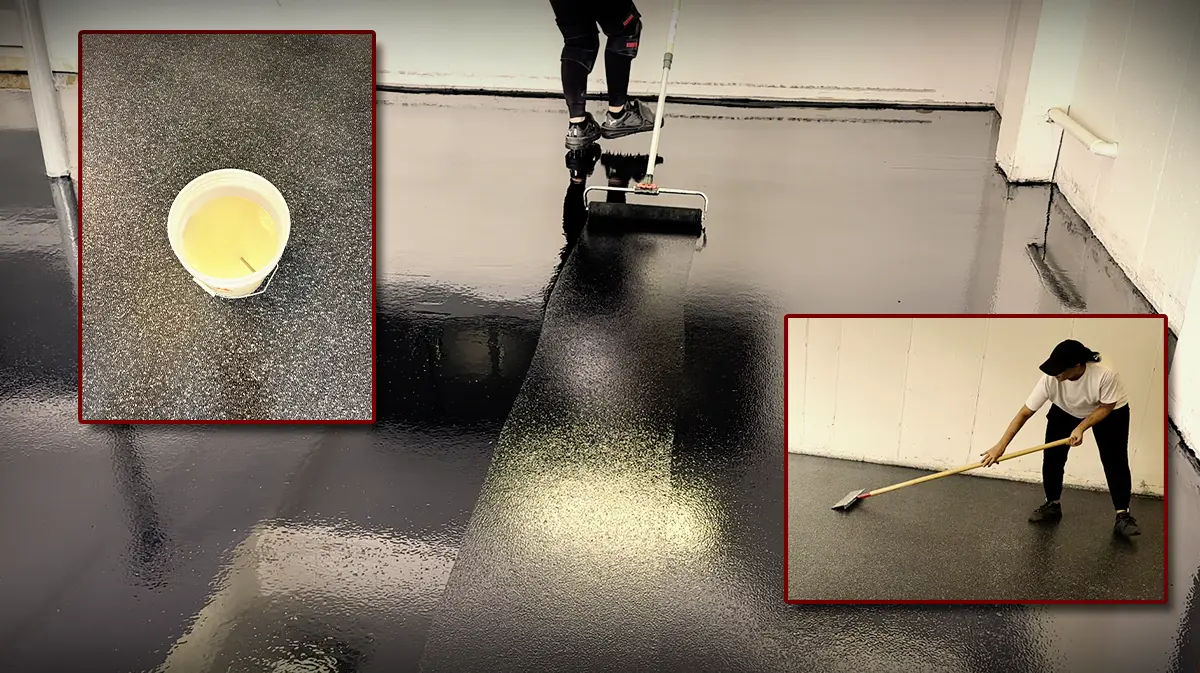

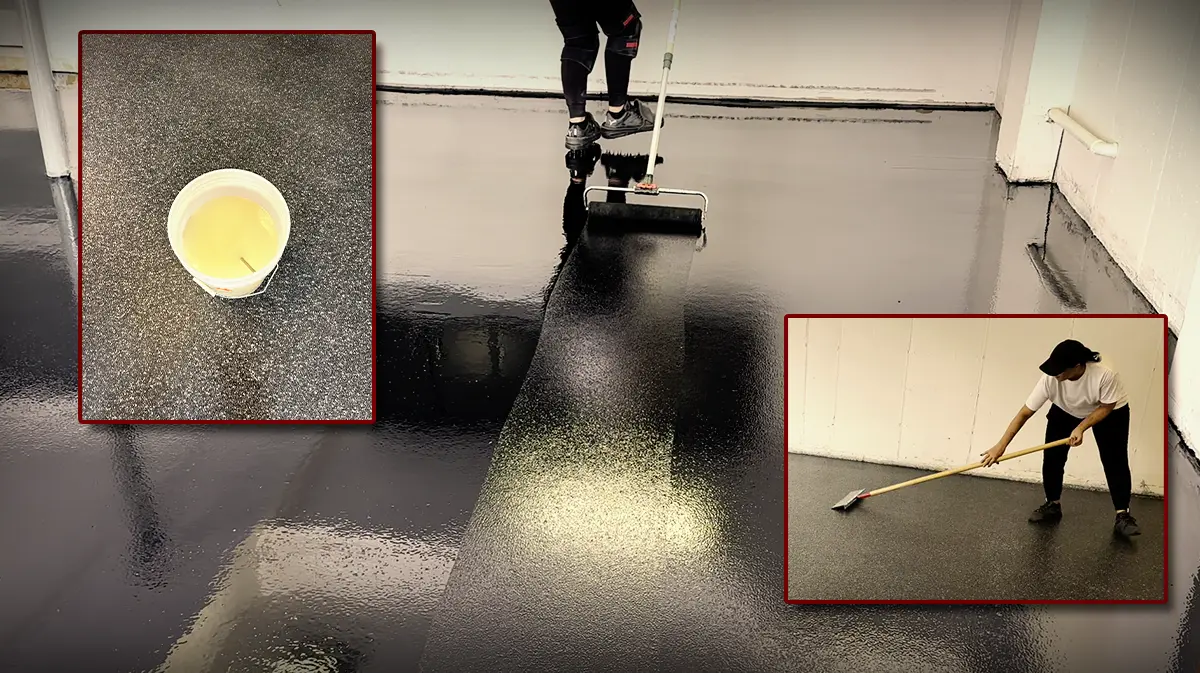

A: An epoxy coating is a two-part system consisting of resin and hardener that chemically bonds to the concrete. This bond creates a highly durable and long-lasting surface, making it perfect for Detroit’s garages and commercial spaces that deal with heavy vehicle traffic, oil spills, and chemicals. A moisture-mitigating epoxy is a superb direct-to-concrete coating. It’s a high-build (thick) coating that acts as a moisture vapor barrier, preventing future moisture related issues. Epoxies do have an Achilles heel: they tend to amber and fade when exposed to UV light.

Epoxy Floor Industry Terms – Q: How does a polyaspartic coating differ from epoxy?

A: A polyaspartic is a fast-curing coating. This means, that once applied, they can be walked on or driven on sooner, often within a few hours. In Detroit, this quick turnaround is particularly useful for businesses or busy households where downtime is limited. Polyaspartic coatings are also UV-resistant, making them ideal for outdoor applications or spaces with lots of natural sunlight. However, polyaspartics and polyureas are not meant for direct-to-concrete application; they make for excellent clear top coats, but poor direct-to-concrete primer coats.

Q: I’ve heard of polyurethane as well. What role does it play?

A: Polyurethane is often used as a topcoat over epoxy or polyaspartic coatings. It adds an extra layer of protection against UV rays, chemicals, and scratches. They are excellent for exterior use, like patios and walkways, where the concrete is exposed to sun and snow. However, polyurethanes can be odorous and are susceptible to hot-tire transfer (aka plasticizer migration). As such, they are simply not spec’d for use in garages. These coatings are best kept for exterior use and where no vehicular traffic is present.

Q: What’s the difference between concrete paint and an epoxy coating?

A: Concrete paint is sometimes mistaken for epoxy, but they serve very different purposes. Concrete paint sits on the surface and doesn’t bond to the concrete the way an epoxy or polyaspartic coating does. While it can offer a quick aesthetic fix, concrete paint won’t provide the same durability or long-term protection. In a Detroit garage, where heavy vehicles and chemicals are common, an epoxy coating is far superior, as it will resist wear, moisture, and impacts much better than paint.

Q: What exactly is a flake system, and why would I want it in my garage?

A: A flake system involves broadcasting decorative vinyl flakes into the epoxy (direct-to-concrete) primer coating. These flakes not only enhance the visual appeal but also assist in improving slip resistance. In a Detroit garage, where moisture from snow or rain can create slick surfaces, a flake system provides added safety and grip, while also offering a unique, customized look. Full flake system are also the most durable coating systems around.

Q: I’m concerned about moisture in my Detroit basement. How can epoxy help with that?

A: Epoxy coatings are excellent at moisture mitigation. They create a sealed, waterproof barrier over your concrete floor, preventing moisture from seeping in. This is especially important in Detroit, where basements are prone to flooding or high humidity. By applying a high-build, moisture-mitigating, 100%-solids epoxy as the base coat, you can protect your basement floor from damage caused by excess moisture and keep it looking great for years.

Q: What are mica flakes, and how are they different from regular decorative flakes?

A: Mica flakes are natural minerals that are added to epoxy or polyaspartic coatings to create a more reflective, shimmering finish. They offer a more luxurious, high-end look compared to standard decorative vinyl flakes. In high-end Detroit garages or commercial spaces, mica flakes can add an extra touch of elegance while still providing the same durability and slip resistance as traditional flake systems.

Conclusion

GatorGuard offers the protection and aesthetic upgrades you need for your concrete floors. With coatings designed to handle everything from heavy traffic to Detroit’s fluctuating weather conditions, you can trust that your floors will be built to last.

Share this Post