Choosing a garage floor coating can be tricky, especially when you’re faced with two common options: the 1-day polyurea-polyaspartic system and the 2-day epoxy and polyaspartic system. A “1-day” system or “2-day” system literally refer to the number of days they typically take to install in your home or business.

If you’re in Louisville, where the weather fluctuates between hot, humid summers and freezing winters, it’s critical to select the right option. While the speed of a 1-day system is appealing, a 2-day installation offers far more long-term benefits.

What’s Wrong with a 1-Day System?

While the speed and affordability of a 1-day system might be tempting, there are several reasons to think twice before choosing this option. Here are the key drawbacks:

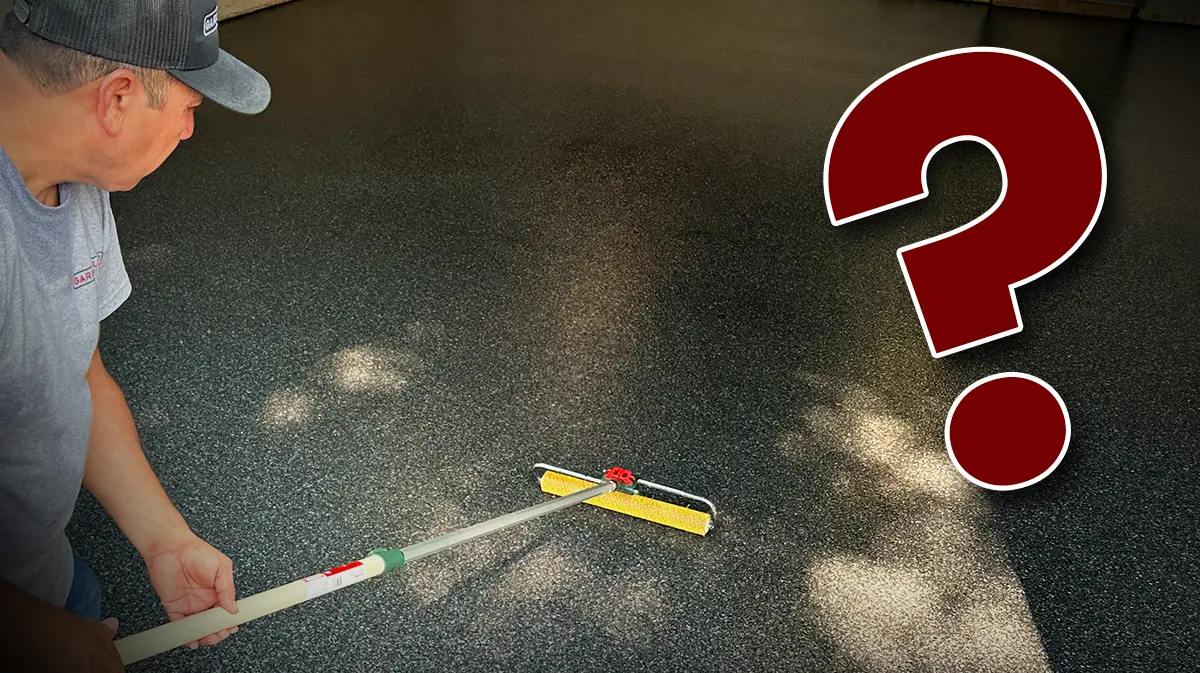

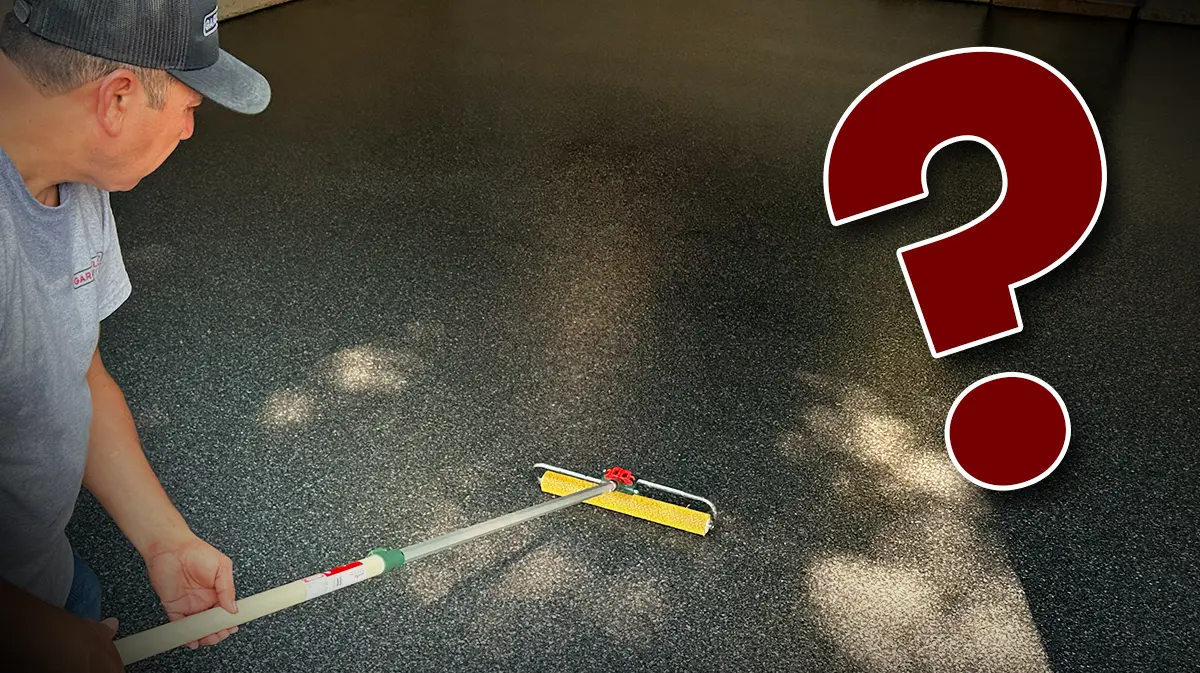

- Surface Prep is Often Rushed: Proper concrete preparation is crucial for the longevity of any floor coating. To get the job done in one day, surface prep is often rushed with 1-day systems to save time.

- No Moisture Barrier: Polyurea-polyaspartic coatings in 1-day systems are applied direct-to-concrete in a very thin layer. They cure so quickly (< 1 hour) that they also don’t deeply penetrate the concrete substrate. As good as these coatings are as clear top coats, they’re simply not spec’d for use as primers (direct-to-concrete). Without a proper moisture vapor barrier, moisture can seep up through the concrete over time, causing the thin, poorly-penetrating polyurea coating to delaminate.

- Single Polyaspartic Topcoat: 1-day systems typically use a “less-than-100%-solids” polyaspartic as their clear top coat…and only apply a single coating!

- Limited Warranty: Many 1-day system warranties exclude moisture-related issues, leaving homeowners on the hook for repairs if their coating fails due to “moisture vapor transmission” or “high hydrostatic pressure”. Funny enough, moisture is the number one cause for coating failures in 1-day systems, so it’s no surprise that it isn’t covered.

Why the 2-Day System Wins Every Time

When you invest in a 2-day epoxy and polyaspartic system, you’re choosing a coating that’s designed for longevity, durability, and high performance. Yes, it takes an extra day to install, but the benefits far outweigh the slight inconvenience. Here’s why:

- Proper Surface Preparation: The 2-day process allows the installers to take the time to thoroughly prepare the concrete. This includes patching cracks, breaks and pitting, and full diamond grinding, both of which are needed to create the perfect concrete profile.

- Moisture Mitigation: The 2-day system starts with application of a moisture-mitigating, 100%-solids epoxy primer. It deeply penetrates and bonds with the substrate and acts as a moisture vapor barrier (MVB). In Louisville, where moisture and humidity is common, this step is essential to preventing future moisture-related issues.

- Thicker Coating: With the high-build epoxy and two layers of 100%-solids polyaspartic topcoats, the total thickness of the system exceeds 35 mils. This ensures superior protection against impacts and wear—perfect for a garage that sees heavy use.

- UV and Chemical Resistance: The dual polyaspartic topcoats are not only resistant to UV rays (preventing fading and yellowing) but also offer excellent chemical resistance. Whether it’s oil spills, road salt, or automotive fluids, your floor can handle it.

- Longevity: With time taken to ensure proper curing, the 2-day system offers better long-term performance, meaning fewer repairs and a floor that looks great for years to come.

Louisville’s Climate Demands More Protection

Louisville’s climate can be harsh on garage floors. Hot summers, cold winters, and plenty of humidity create the perfect storm for concrete moisture issues. The 2-day system addresses these weather challenges with a coating process that’s designed to last.

- Humidity Control: The epoxy primer acts as a moisture barrier, preventing damage caused by Louisville’s frequent humidity and condensation.

- Freeze-Thaw Resistance: As temperatures drop, the moisture-mitigating epoxy helps your floor withstand the freeze-thaw cycles that can crack and peel thinner coatings.

- UV Durability: Louisville’s sunny summer days won’t fade or damage your garage floor, thanks to the UV-resistant polyaspartic topcoats.

Ready for the Best Floor? Call GatorGuard Louisville for a Free Quote

Don’t settle for a quick fix that may not last. GatorGuard Louisville offers the highest-quality 2-day epoxy and polyaspartic garage floor systems. If you’re looking for a floor that’s built to stand up to Louisville’s climate and the rigors of daily use, contact us today for a free quote. Let us give you a garage floor you’ll be proud of for years to come.

Share this Post